-40%

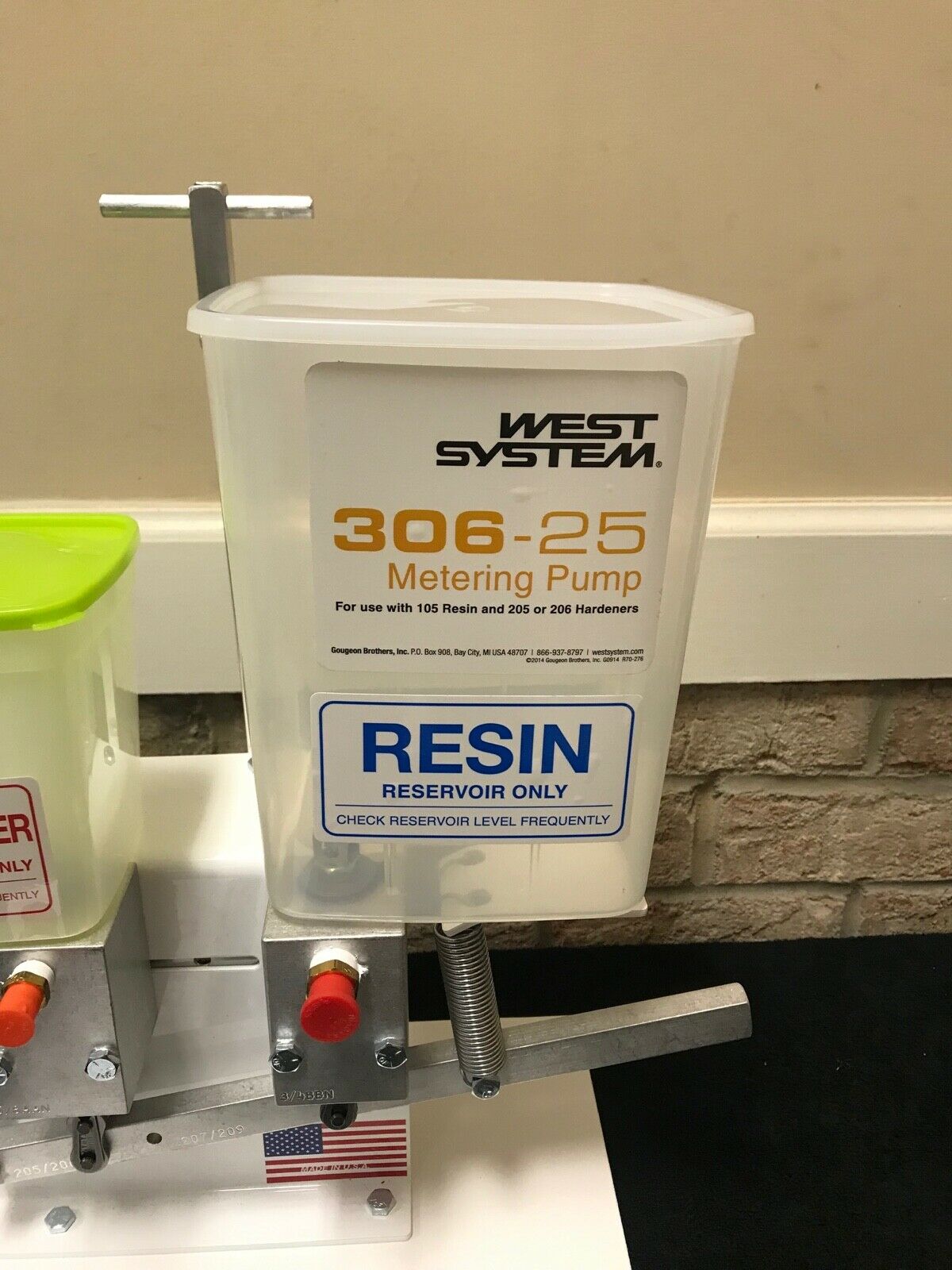

Brand New West System 306-25 Model A Epoxy Metering Pump System 5:1 Ratio 30625

$ 158.37

- Description

- Size Guide

Description

This is a Brand New West System 306-25 Model A Metering Pump System (5:1 Ratio). Original cardboard shipping box has damage due to Amazon shipping. I opened box to inspect for damage to item and it's New & Perfect!! Save some $$$$ if you're not concerned with a perfect cardboard box. 1st photo is stock photos but others are of actual item.Free Shipping!!

West System Details below;

The 306-25 Metering Pump reduces mixing time and waste on large projects. Great for metering larger quantities of

105 Resin

and

205 Fast

or

206 Slow

(5:1 ratio) Hardeners. A carrying handle allows you to move the pump where the work is. Reservoirs hold one gallon of resin, one quart of hardener. Dispenses approximately 0.5 fl oz of resin/hardener per pump stroke (about 1 qt per minute).

Our

306 Model A Dispensing Pumps

consist of two separate, parallel systems, one for the resin and one for the hardener. Each has a spring-loaded poppet type intake valve, a piston with an O-ring seal, and a spring-loaded ball check exhaust valve. The pump will deliver approximately ½ oz. of resin/hardener per pump stroke. The reservoirs hold one gallon of resin and one quart of hardener.

Priming

CAUTION—Remove all materials from Resin and Hardener reservoirs and be sure the reservoirs are clean before filling.

Prime the hardener system first. Fill the hardener reservoir with hardener. Pump the operating handle until hardener flows evenly from the spout without emitting air. Ten to twenty strokes of the handle should produce hardener at the spout. If not, use a stick or dowel to hold down the intake valve screw head inside the reservoir while slowly pumping the handle. This will allow trapped air to escape the valve and hardener to reach the piston.

After the hardener side is working properly, fill the resin reservoir and prime the resin system. Dispense the resin and hardener into separate, clean containers, or the original resin and hardener cans. After both systems are working, return the dispensed resin and hardener to the proper reservoirs.

Note: When filling the reservoirs do not get any resin in the hardener reservoir, or hardener in the resin reservoir. Always keep one reservoir covered while filling the other. Keep reservoirs covered at all other times to prevent contamination. Once primed, the pump should not be allowed to dry out. Dried hardener can damage the piston seal and clog the passages and valves. For this reason, the ratio is not checked at the factory.